Last year, FLEET researchers at RMIT developed a ground-breaking new method of depositing atomically-thin (two-dimensional) crystals using molten metals, described as a ‘once-in-a-decade’ advance.

Study co-author FLEET PhD student Rebecca Orrell-Trigg will discuss the liquid-metal deposition on RRR radio show Einstein a-Gogo in May

Earlier this year, the same research team expanded the new method from controlled to ambient conditions, and has properly characterised the growth mechanisms for key tin oxides, which should allow improved control of target oxide growth.

The technique developed at RMIT last year introduced liquid metals (gallium-based) as a successful reaction environment for the synthesis of desirable, atomically-thin oxides that were unattainable using prior methods. It’s a process so cheap and simple that it could be done on a kitchen stove by a non-scientist.

While the initial study used costly, specially-designed alloys and an often tightly-controlled environment, this latest research has confirmed that high-quality 2D materials can be formed in ambient conditions using cheaper liquid tin, simplifying future research and applications.

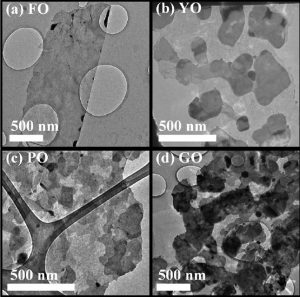

Researchers also characterised the growth mechanism for the first time, creating a ‘road map’ of crystal formation and growth. Such growth proved surprisingly complex, with small ‘islands’ of tin-oxides (SnOx) forming on larger, perfect 2D tin monoxide (SnO) monolayers, before thickening and taking on more oxygen to become tin dioxide (SnO2).

Future applications

Transmission electron microscopy (TEM) images of (a) fresh, (b) yellow, (c) pink and (d) grey tin oxides

This simple, repeatable method of growing 2D tin-oxide crystals can be expanded to other low-melting point liquid metals and their alloys.

Having properly characterised growth mechanisms, researchers believe it should be possible to control the rate of surface oxide formation by careful control of the atmospheric oxygen content, and hence control the number and thickness of oxide layers and resulting stoichiometry.

Tin oxides are of particular interest as 2D materials. Electronically, they can be both p-type (SnO) or n-type (SnO2) semiconductors, which is of great interest to field effect transistor (FET) designers.

The study

Evolution of 2D tin oxides on the surface of molten tin was published in Chemical Communications in January 2018.

The study was conducted using the facilities and expertise of the Australian Microscopy and Microanalysis Research Facility at the RMIT Microscopy & Microanalysis Facility, and the Micro Nano Research Facility at RMIT. Co-author Torben Daeneke received support from the RMIT Vice Chancellor’s research fellow scheme.

Last year’s study was published in Science, and widely discussed, including at ScienceDaily and the ABC. See the RMIT website for more information.

2D materials and FLEET

Deposition of atomically-thin materials is key to FLEET’s quest to develop a new generation of ultra-low energy electronics. Study co-authors Rebecca Orrell-Trigg, Ali Zavabeti, Torben Daeneke, Paul Atkin and Kourosh Kalantar-Zadeh work within FLEET’s Enabling Technology A, developing novel two-dimensional semiconducting materials through theory, synthesis, and characterisation.

FLEET is an Australian Research Council-funded research centre bringing together over a hundred Australian and international experts to develop a new generation of ultra-low energy electronics.

Want to learn more?

- Kourosh Kalantar-Zadeh kourosh.kalantar@rmit.edu.au

- Follow FLEET at @FLEETCentre

- Website FLEET.org.au

- Youtube: future solutions to computation energy use

- Subscribe to FLEET news FLEET.org.au/news

IMAGES

Melbourne MP Adam Bandt and FLEET RMIT node leader Kourosh Kalantar-Zadeh studying liquid gallium