A Meet FLEET innovation-and-industry event poster

The Challenge

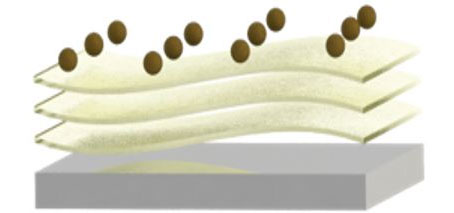

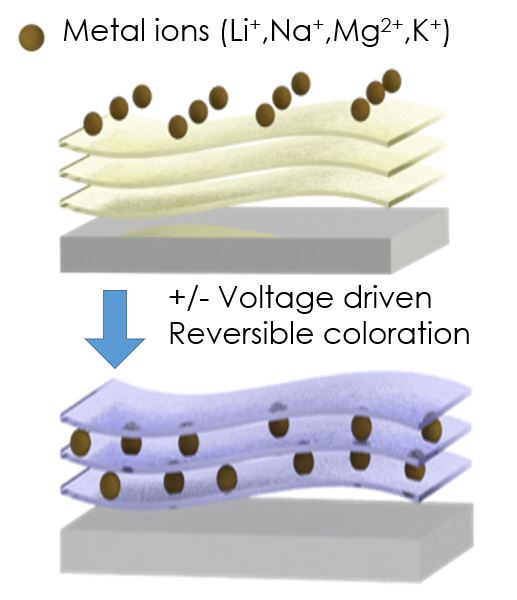

Fig 1: Schematic diagram showing electrically-driven metal ion intercalation in layered MoO3 films causing electrochromism, a colour change phenomenon in response to applied electrical voltage.

As urban centres around the world grapple with the dual challenge of rising energy demands and the urgent need to reduce carbon emissions, the integration of smart infrastructure becomes pivotal. A significant amount of a city’s energy is consumed by building heating, cooling, and lighting. Innovations like tint-adjusting windows, heat mirrors, and selective light absorbers can drastically cut energy use, directly reducing carbon footprint. As ‘smart cities’ develop, these technologies will become integral, not just boosting energy efficiency but also ensuring inhabitants’ comfort and health by shielding them from unwanted radiation, paving the way for a sustainable urban future.

The Solution

We aim to develop a chemical vapor deposition technique to produce large-scale MoO3 films on ITO glass that show electrochromic properties in the visible and near infrared. We have designed an electrochromic device with an ITO-electrolyte-MoO3/ITO structure. This device can achieve energy-efficient colour switching across a tunable wavelength range.

Key Benefits

-

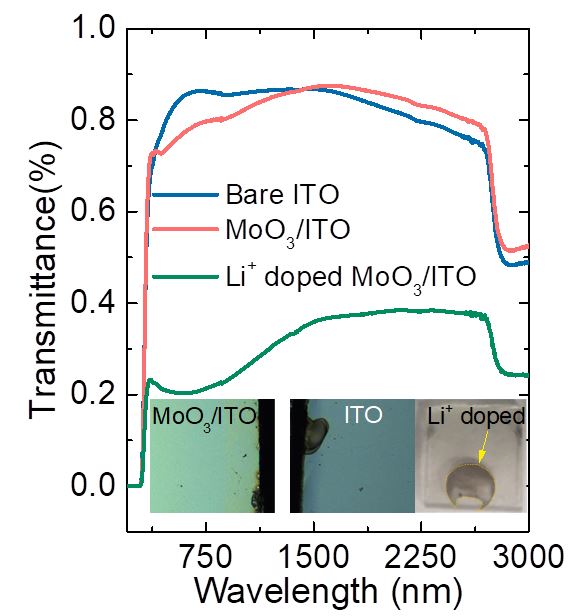

Fig 2: Transmittance measurements of MoO3/ITO films, compared to bare ITO and Li+ doped sample, indicate MoO3 film slightly affects the transparency of ITO, exhibits noticeable colour change when Li+ is intercalated.

CVD deposition method is cost-effective and can help realise uniform and large coverage.

- Layered structure of the material → more ions can penetrate and participate in colour changing → better coloration.

- Low cost material with relatively low environmental pollution.

- MoO3 is a wide band gap material (highly transparent in the bleached state).

Development Stage

- Technology Concept completed. Further improving the film quality and device cycle times. Seeking strategic partners

Brief Description & Differentiation

The aim of this project is a thin film development for use in residential and commercial window glass. This will enable the creation of a smart (active) window capable of multiple colour changes through numerous cycles.

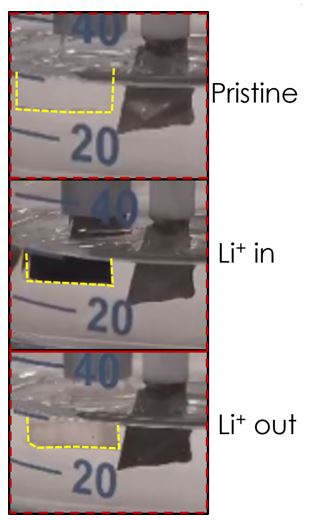

Fig 3: During electrochemical measurements conducted in a LiClO4 solution, the MoO3/ITO films (yellow dashed lines) exhibit reversible colour changes at varying voltages.

We have developed a CVD method of forming a MoO3 layer on an ITO substrate. After depositing MoO3, the substrate’s transparency undergoes slight alterations, suggesting the film retains its clarity (Fig. 2). By using LiClO4 as the electrolyte, we can control the film’s colour and transparency by applying positive or negative voltages, driving the Li+ ions in and out of the MoO3 film, realising a platform suitable for a smart window. (Figs 2 & 3). This has been demonstrated also with other ions including K+, Na+ and Mg2+, realising spectrally selective coatings.

Intellectual Property

Under preparation

Key Publications

- Data collection ongoing for publication.

More information

- Contact Prof Sumeet Walia, RMIT University sumeet.walia@rmit.edu.au

- Contact A/Prof Enrico Della Gaspera, RMIT University enrico.dellagaspera@rmit.edu.au