Centres of Excellence, which bring scientists together from different fields – such as material science, electronics, chemical engineering and theoretical physics – with common purpose, inevitably spark discoveries that weren’t even considered at the outset.

As a consequence of ongoing collaborations within FLEET, researchers have made a series of liquid-metal discoveries.

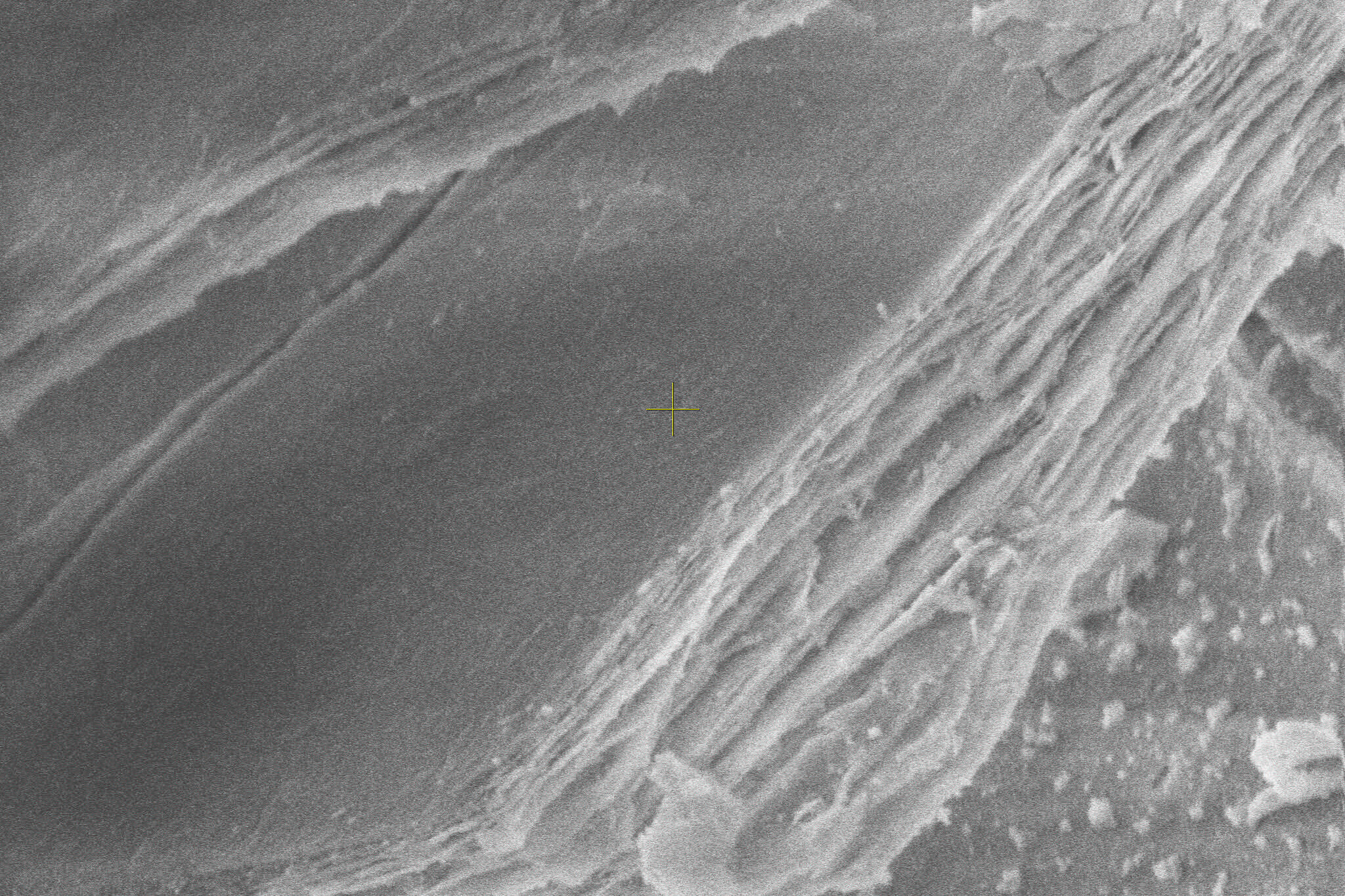

Liquid-metal interfaces were discovered to form a successful reaction environment for synthesis of the 2D materials FLEET was investigating for future low-energy electronics.

And as such an entirely new process was born, allowing access to previously unattainable novel materials.

This ‘once in decade’ advance was described as so cheap and simple that it could be done on a kitchen stove.

Material synthesis technologies utilising metals that are liquid at room (or low) temperatures, such as gallium (30°C), indium (157°C), tin (232°C) or bismuth (271°C), allow:

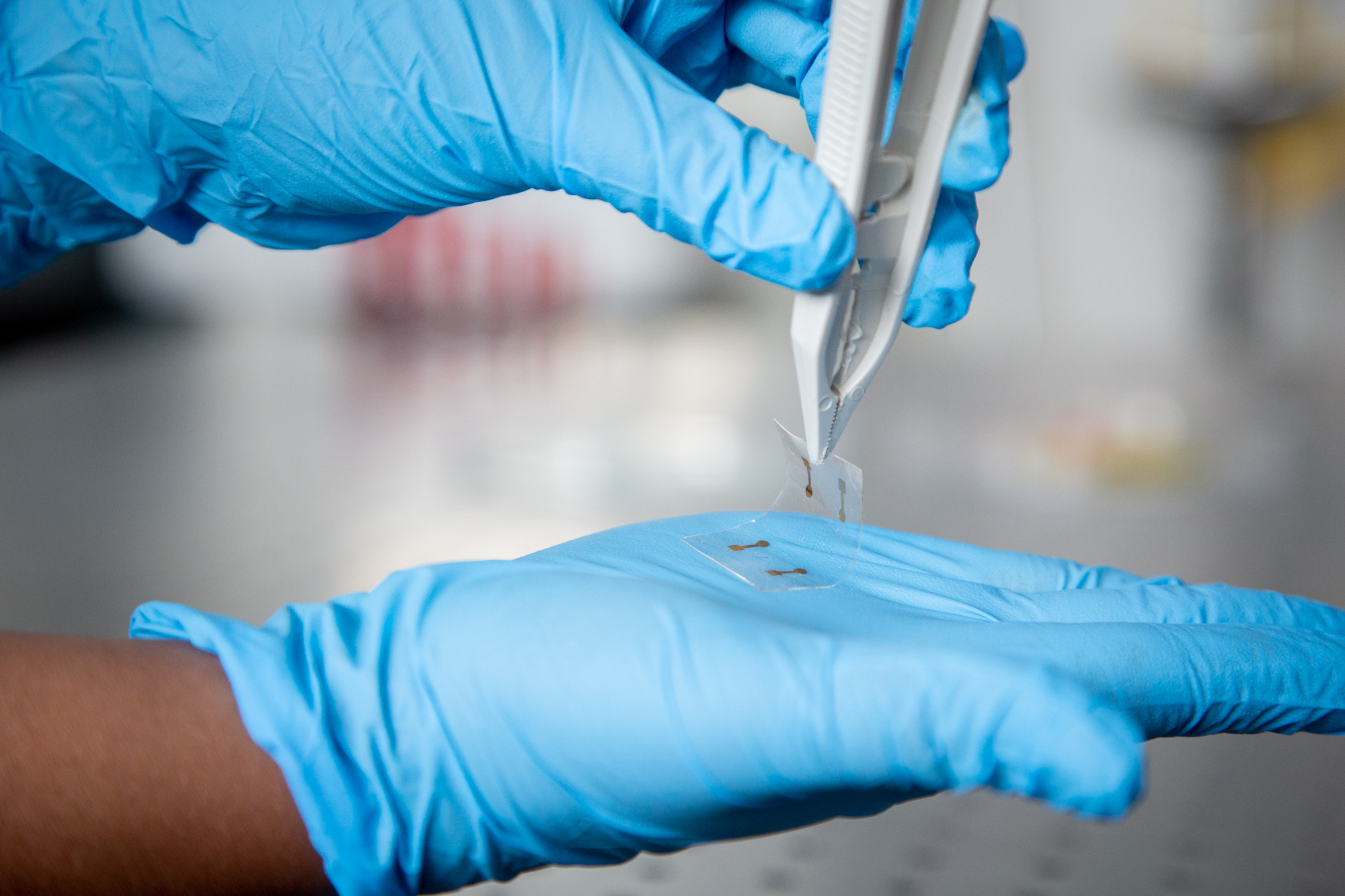

- Liquid metal touch printing of new electronic materials

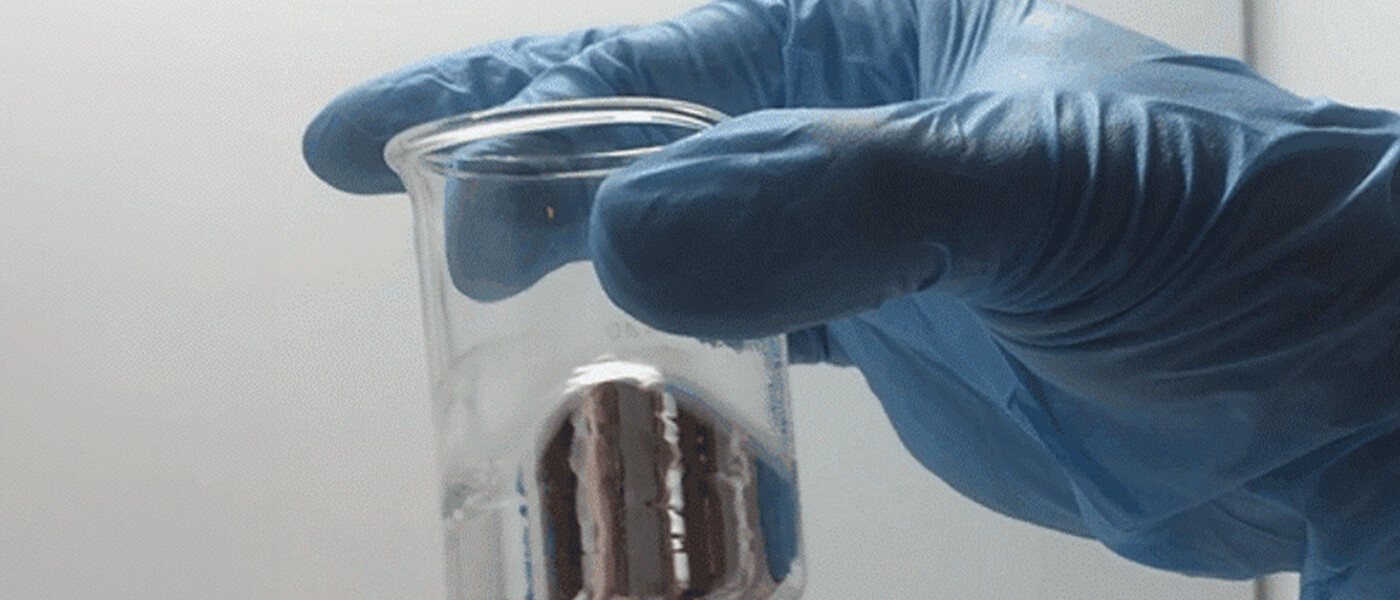

- Protective layers for delicate novel materials, allowing integration into functioning devices (for example, allowing room temperature exciton trapping)

- Never-before synthesized materials offering new applications.

And those new materials are just the start…

The new liquid metal processes allow advances with even more-direct benefits for our environment, and for a more-sustainable future, including innovative carbon-capture technologies, water filtering, and low-energy hydrogen catalysis for alternative energy systems.

These technologies have all sparked further research, attracting external funding, and at least one spin-off company has been formed.